WASHI PAPER

和紙

Sheets of strength and beauty

We offer a selection from Sugihara Shoten, a washi wholesalers, that have been established in 1871 by Sugihara Hanjirō to supply high-quality paper from all around Echizen including the work of the regional industry’s ‘Living National Treasure’ Iwano Ichibei IX.

Please inquire about customization and many different application possibilities in Japanese restaurants, private homes, design projects.

MORE INFO

WHAT IS WASHI?

Washi – literally ‘Japanese paper’ – is made from three different plants: kōzo (mulberry), mitsumata and ganpi, the long fibres of which create incredibly durable papers. With a 1500-year old history, the largest washi-making area in Japan is a cluster of five villages in Echizen in Fukui Prefecture. The high quality paper was used for many things including official documents and even the first Japanese banknotes.

HOW IS WASHI MADE?

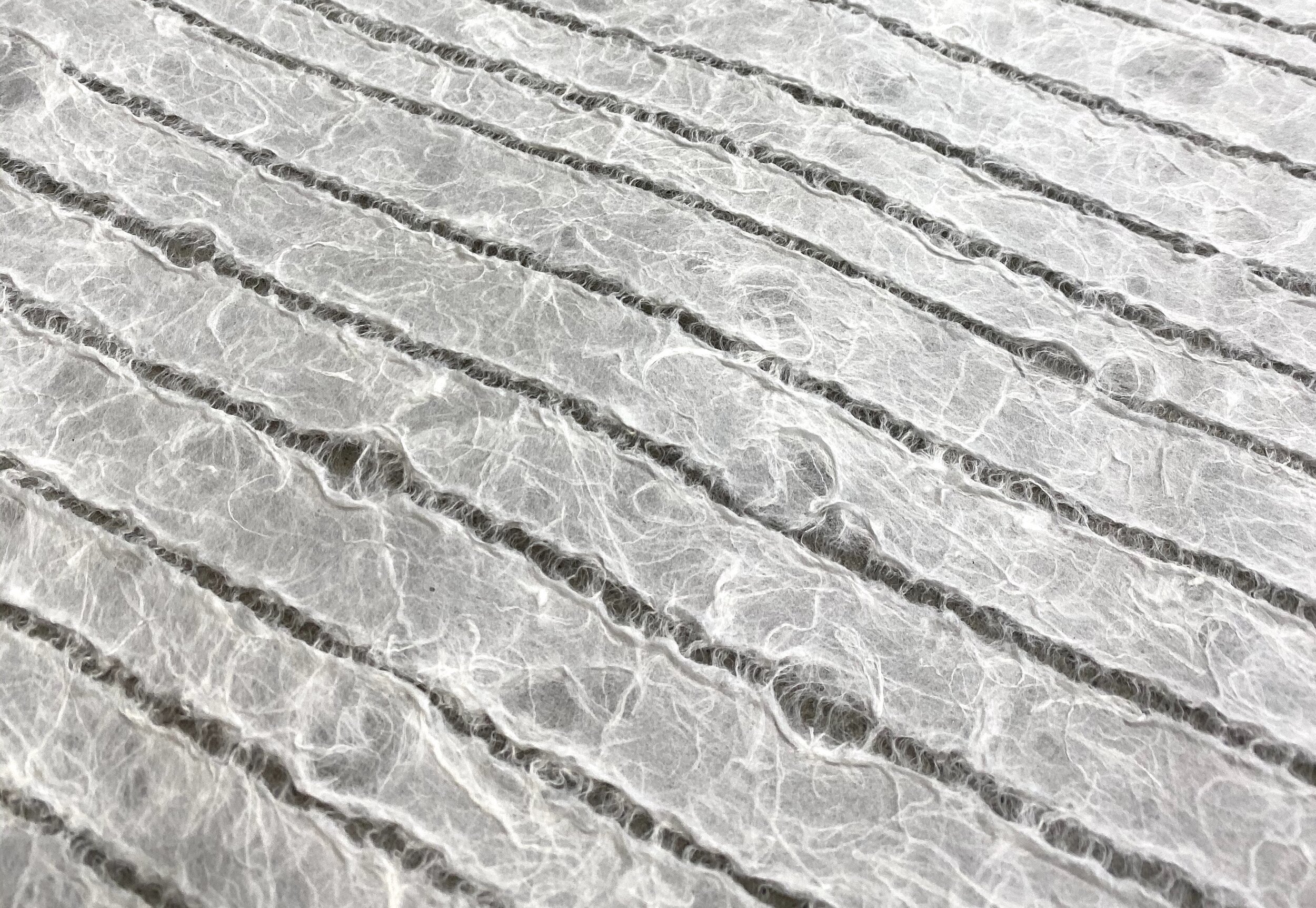

There are two methods of making paper, tame-zuki and nagashi-zuki. The tame-zuki paper making method was passed to Japan from ancient China. It involves placing the pulp mixture made from plant fibres and water onto a wire-netted frame screen that is kept horizontal and shaken back and forth, left to right, to mingle the fibres well. The fibres used are short and the resulting paper is less dense.

Washi is most commonly made using the nagashi-zuki method developed in Japan about 1,000 years ago. Using this method a viscous substance made from plants is added to the pulp mixture, and a bamboo-netted frame screen is rocked back and forth and from side to side so that the mixture flows over the screen. This allows the paper to be made with longer fibres, which become tightly interwoven, resulting in a stronger product.

HOW TO USE WASHI?

This strong, thin paper is used not only for books, drawings, and paintings, but also as a material for architecture and everyday items including sliding paper screens and partitions (shoji and fusuma), umbrellas, andon lamps, and garments. When machine-made paper from the West began to be imported into Japan during the Meiji Period (1868–1912), people referred to Japanese paper as washi in order to distinguish it from Western paper. Washi (和紙) literally means 'Japanese paper'. 和 (wa/Japan) + 紙 (shi/paper) = washi, handmade Japanese paper.

WHERE IS WASHI MADE?

Although washi has been made throughout Japan for centuries, there are certain production centres famous for quality – including Echizen, Mino, Sekishu, Tosa, and Inshu – that continue to make washi today. One of these in particular, Echizen washi has been highly valued throughout history for its quality and ingenious design. Examples include Echizen-hosho and Echizen-torinoko paper, which were used by the samurai and nobility for official purposes.

WASHI SELECTION

Please note there are hundreds of varieties.

As they would say in Echizen, there is nothing they cannot do from Washi.

Please contact us for more info.

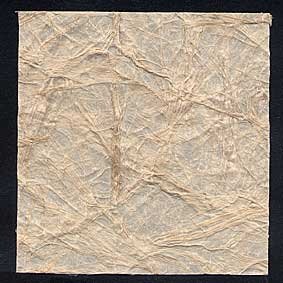

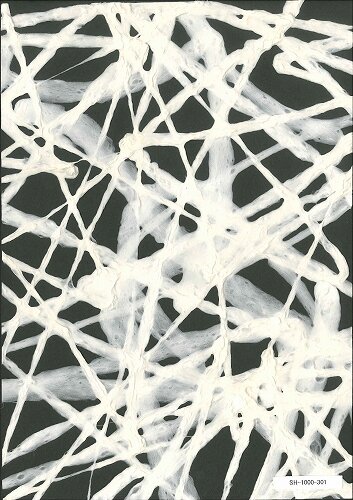

Ordering code : SH-1000-301

Mitsumata

600 x 900 mm / 420 AED

1000 x 1000 mm / 700 AED

1000 x 2000 mm / 1,400 AED

1500 x 3000 mm / 3,150 AED

2100 x 3000 mm / 5,500 AED

1300 x 3800 mm / 4,100 AED

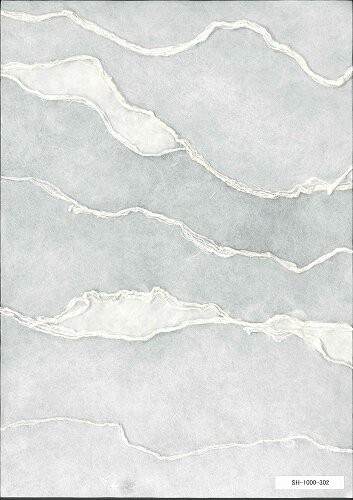

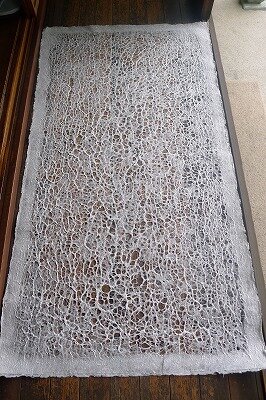

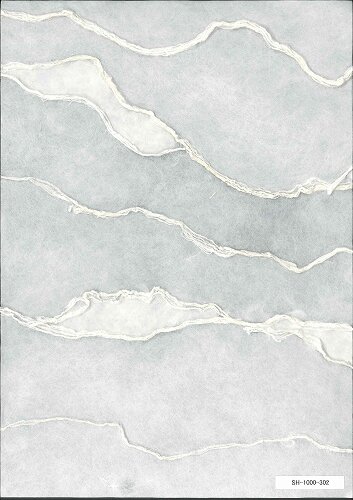

Ordering code : SH-1000-302

Kozo & Abaka

600 x 900 mm / 420 AED

1000 x 1000 mm / 700 AED

1000 x 2000 mm / 1,400 AED

1500 x 3000 mm / 3,150 AED

2100 x 3000 mm / 5,500 AED

1300 x 3800 mm / 4,100 AED

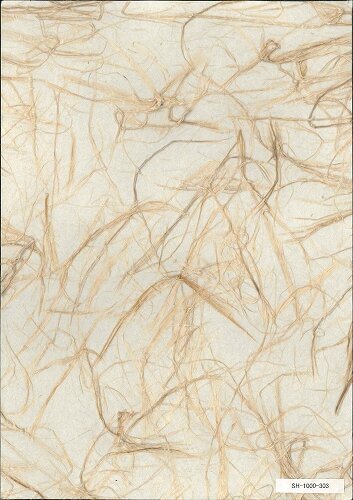

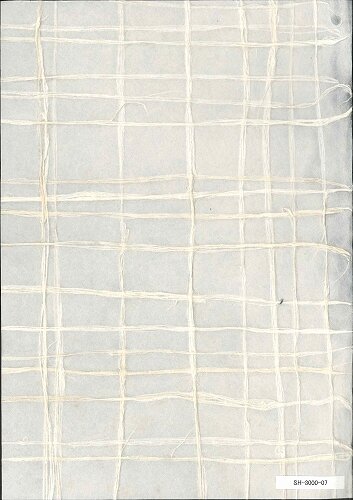

Ordering code : SH-1000-303

Gampi

600 x 900 mm / 435 AED

1000 x 1000 mm / 605 AED

1000 x 2000 mm / 1,225 AED

1400 x 2200 mm / 3,500 AED

1050 x 3000 mm / 3,500 AED

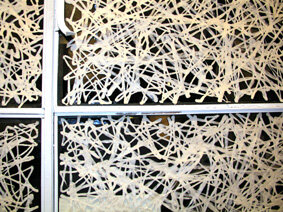

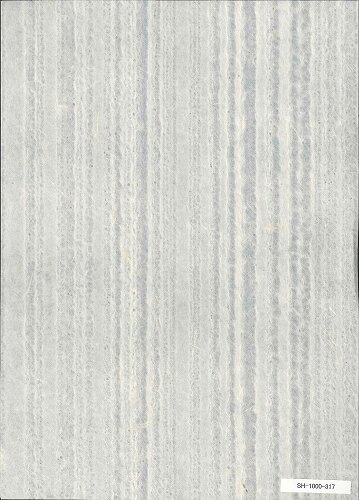

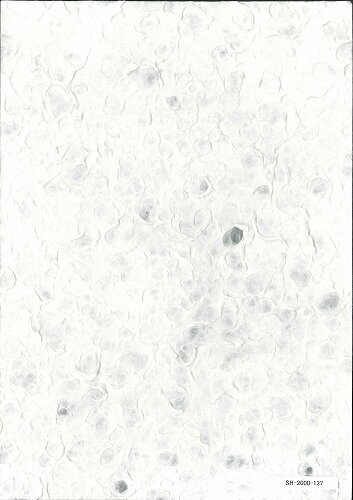

Ordering code : SH-1000-317

Koz & Abaka

600 x 900 mm / 315 AED

1000 x 1000 mm / 525 AED

1000 x 2000 mm / 1,050 AED

2200 x 3000 mm / 9,500 AED

2200 x 5000 mm / 15,750 AED

2200 x 7000 mm / 22,500 AED

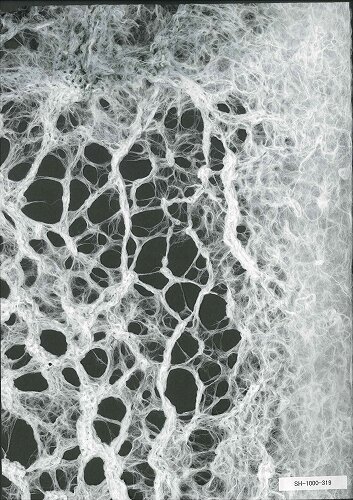

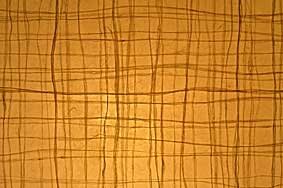

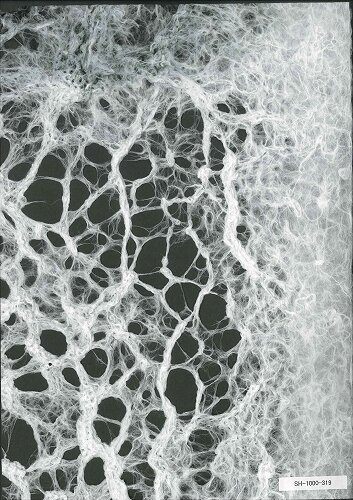

Ordering code : SH-1000-319

Kozo

600 x 900 mm / 435 AED

1000 x 1000 mm / 525 AED

1000 x 2000 mm / 1,050 AED

1000 x 3000 mm / 1,575 AED

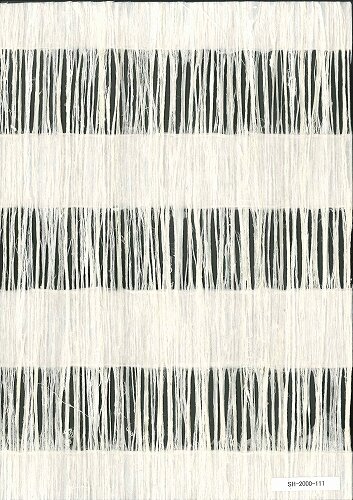

Ordering code : SH-1000-321

Mitsumata

600 x 900 mm / 475 AED

1000 x 1000 mm / 775 AED

1000 x 2000 mm / 1,575 AED

1500 x 3000 mm / 3,550 AED

2100 x 3000 mm / 5,500 AED

1300 x 3600 mm / 4,100 AED